Home _ Infrastructure

We operate a highly advanced press facility equipped with Digital, Sheetfed, and Heat-set Web Offset presses, offering exceptional versatility, consistent output, and rapid turnaround times. Our four fully integrated, independently functioning production units enable seamless job transfer across machines, optimizing workflow efficiency. Equipped with inline quality control systems, including Spectrophotometers and Densitometers, we ensure precise color calibration and print consistency. Continuous investment in cutting-edge, eco-efficient printing technologies reinforces our commitment to innovation, sustainability, and delivering superior print quality at every stage of production.

Mitsubishi stands at the forefront of printing technology, delivering cutting-edge innovations for superior print quality.

The Shinohara 75 4 Colour delivers exceptional precision, capturing intricate designs and fine details with remarkable accuracy.

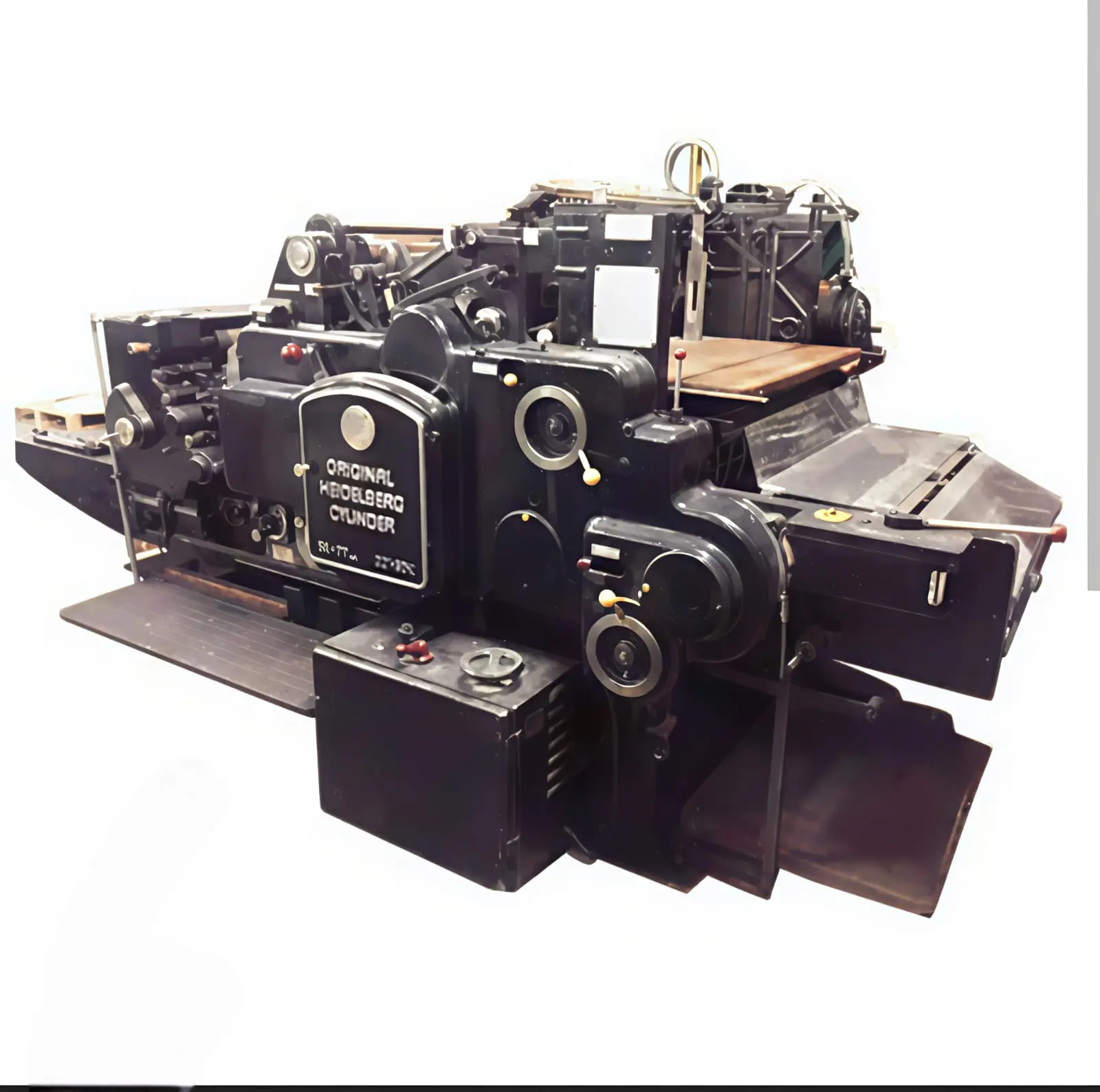

The Heidelberg 2 Colour (UV Drip Off) enhances prints with glossy accents, highlighting specific elements for a striking visual effect.